|

|

Post by 90GTVert on Jul 12, 2015 18:27:22 GMT -5

If there's profanity in my vids it's usually a reaction while riding. The things said in my helmet about cars, pedestrians, and unexpected events would make my videos all R rated. If anyone ever meets me I'll probably curse with or at you lol, but I try to keep it out of the vids for the most part. I can assure you my scooters sometimes deserve it though.  |

|

|

|

Post by aeroxbud on Jul 13, 2015 4:44:10 GMT -5

If I had to edit hours and hours of video, like you Brent, then you would see  Keep up the good work |

|

|

|

Post by kagetenshi on Jul 16, 2015 10:08:32 GMT -5

I hope that I don't end up with this many issues on my taotao. Jeez...how many aspirin did it take to fix all the headaches this thing has given you?

|

|

|

|

Post by 90GTVert on Jul 16, 2015 11:58:56 GMT -5

I've said it before, but to be fair some of the stuff I've dealt with wouldn't really bug a lot of people I don't think. If you don't put a tach on it and record your speed and RPM and 0-30 times and so on, you'd prob never even notice some of the things I've been complaining about in the CVT. I'm doing it for the project's sake mostly. The fact that it broke down on me 1 time in 2 years doesn't make it a nightmare. At least generally I've been able to count on it getting me home so far. Still it has not changed my opinion that Chinese scooters are best suited for people that are at least willing to work on them, better yet enjoy it to some degree, or have an exceptional local dealer. That said, I messed something else up. lol After the pickup coil was installed, RPM picked up all around. At first I thought the belt must have worn a little or something. Power didn't seem much different.I took the CVT cover off to check the belt, which was fine. I switched to 0.5g heavier sliders to try it out that way. I've got 2 M6 Time-Serts in the case for my CVT cover bolts. I'm very guilty of not using all bolts in the cover because my CVT cover comes off frequently for checks and tuning so that probably doesn't help. When I went to tighten the bolt nearest the starter bendix up top it felt like it didn't wanna tighten. It's felt odd for a while. Turned it back out and the Time-Sert and case threads came out.   So it was already an oversized hole in the case at that point. I checked it out and decided to patch it up by going to an M8x1.25 bolt there. There seemed to be enough meat on the cases and cover to make it do-able so I did it.  I had to drill the hole in the CVT cover to accept and 8mm bolt and I had to use a cap screw because there's no room to tighten a standard 6 point.  Regarding the tuning, I've found that the scoot is now slower than it used to be. At least slower than it was in the last updates when it was timed in the 17.7-17.8 second range for 0-30s. From looking at vids of recent runs vs vids of the runs in the 17s, it looks like it used to hold a much more steady RPM range for 0-30. Apparently all stock replacement variators are not created equal. I have no plans to go on the hunt for the best replacement though. As long as it will be consistent now, I can try different mods. This may bump variators up on the to-do list though. I was going to do air filters, just to get it out of the way even though I suspect the results will be unimpressive, but I may try out a couple of aftermarket variators for the update after the next update whenever I get to that point. I'm hoping to do 2 sets of 0-30s today with sliders 0.25g apart so I'll have 0-30s to compare with 5g, 5.25g, and 5.5g and see which I should stick with. Allegedly the wind would die down by now, but it's still 10MPH or so. Now the forecast says it'll die down later, so we'll see. I've already rode it to check mileage and cruising with the 5.5s and 5.0s on 2 late nights. Need to do that with the 5.25s as well. This consistency stuff is so much more difficult that just building a fast scoot. I could have it doing 40-50MPH within the next couple of days if there were no project to worry about, but I'm always pulling my hair out over little details just trying to keep it working on par. To add to the fun, one road I do 0-30s on in the woods so it blocks wind better was freshly tar and chipped. I've done runs on it and a nearby road back to back and the tar and chip has been slower 2 of 3 times. Once it was very close, the others were off by almost a second. It's sure not spinning a tire (barely moves when I first take off) but I guess there's more friction/resistance with the tar and chip. That or other conditions were at play, even though both go in very nearly the same directions. I'm extremely glad I installed a wideband when this project started. That thing is a lifesafer. It really has cut my carb tuning time. Pretty much just make a change and watch the gauge. Plus when something does go south I can look down and see if it's air/fuel related or not. By watching the wideband, I noticed part throttle has been rich. It hasn't felt any different that I can notice with just a butt dyno. I switched the needle to the leanest position (from the next to leanest). I did do a roller weight swap, but one ride I got 80.3MPG. The next, after needle change, I got 90.0MPG. I haven't been taking as many rides on the TaoTao in recent months as I was at one point, so it's still a little surprising to me to look up and see that I put in <$1 worth of premium at $3.13-3.14/gal sometimes for over an hour ride. |

|

|

|

Post by 90GTVert on Jul 23, 2015 22:42:58 GMT -5

The slower 0-30s have annoyed me. While I can't actually notice it too much just riding, at times it's averaging 20+ seconds 0-30s. I did a little checking to see if anything was obviously wrong. Started with a simple valve lash check, which was fine. I had specs from the first compression tests I did on this engine and I've made no engine mods that should alter them so I re-did the tests. Originally I got 165psi with the Actron tester and 183psi with the Snap-On compression tester. This time I got nearly the same results :   I checked base timing to verify that the new pickup coil was achieving the same advance as the old one. It was 13° BTDC, like the last one. On to the CVT then. I've been watching the variator as I racked up miles on it trying to see how it would last. I think the oilite bushing has been a nice improvement over the stock stuff, but I've noticed other parts of the variator are showing their age. Here are a few looks at the bushing with ~1800 miles showing no major signs of giving up on me like the stock stuff that failed in as little as 700 miles :    I did notice a green tint to one end of the bushing if I held it just right, but only right on the end facing the engine/ramp plate. Couldn't catch it in a pic. Here are the ramps showing some wear. It looks bad, but it doesn't feel as it would appear. I can barely feel them :   The guide posts are wearing down as well :  Here's the drive boss, which also feels smooth though it doesn't look like it :  The face of the variator has mild wear. It can be seen using a straight edge and light :    I've had a backup variator on hand for a long time now, as well as oilite bushings, so I decided to see if a new replacement variator would change performance any. Here's the replacement and it's stock steel bushing :   Here's the oilite and the stocker :   I got the same measurement for the oilite and the old bushing in this variator. Both came out to 0.0013" interference fit. I used Loctite 603 and staking, but did no stippling this time. Hopefully it will hold.   While I was at it, I wanted to check the angle of the grooves in the NCY torque driver. I had tried both sets of grooves recently, but I was paranoid that I may have put it back together wrong or something. I did have it in the "correct" 40° grooves. I noticed that the grooves are wearing in one spot though. I believe the pic below makes it look worse that it is. The pins also have flat spots. I put it back together for now, but I did order a new NCY torque driver that should be the same as this one from Enviromoto. Hopefully I've got pins around here to replace these. I wanted to test it with just the variator done rather than replacing most of the CVT at once.   Today I took it for a ride to see if it's in the ballpark or if the tune would be way off. I wanted to work on the tune, but it was windy and I'm not a fan of dialing in a tune with much wind. I figured a bit of a ride would also let me see if the bushing stays put in the variator. As-is it's close, but revving slightly too high. Fine to ride around and put a few miles on. About 15 miles into the ride I rolled up to a stop sign and it died as I braked. Very much like it did before I replaced the pickup coil when I had to load it in the truck to get it home. My hip has really been bothering me lately so I was not looking forward to a 5-6 mile push. I pushed it across the road to a safe spot and wiggled wires and took the gas cap off and little stuff that I could do without tools. After a few minutes it started again. I really have no idea why. I hopped on and rode it home making sure I held the throttle a bit at every stop just in case. Once I was home I tried to replicate the engine stopping, but I couldn't. I let it idle for quite a while and it ran fine. I wiggled wires and whatnot again and it kept on ticking. I thought maybe it's something with the idle circuit or air cutoff valve since it's happened when I closed the throttle coming to stop signs both times. I took the carb apart and thoroughly cleaned it and stuck bits of it in the ultrasonic cleaner. I took 537 pics (not exaggerated) along the way so maybe I'll be able to put a few up somewhere in case they're of any use for carb cleaning help.  It did appear that the pilot jet was at least partially clogged. They're hard to see through though and it's never acted like a clogged pilot jet to me. If that's all it was I'd think it would restart, especially with the accel pump working, even if it died out quickly. I noted my mixture settings and it ran the same with the old mix settings after cleaning. Didn't change anything that I could notice just from it sitting around idling or being revved. |

|

|

|

Post by 49dykon on Jul 24, 2015 9:34:48 GMT -5

That's really interesting bc my scoot has done the same thing at stops it will die but only every now and then. I was thinking it was a carb issue maybe just not being tuned well enough (sometimes I get lazy and don't tune it for a couple weeks) but I thought it was interesting that you seem to be having a similar problem

|

|

Moat

Scoot Member

Posts: 88

|

Post by Moat on Jul 24, 2015 11:48:52 GMT -5

Brent - the Oilite bushing in the old variator looks a bit dis-colored due to heat (blue/turquoise swirlies) - curious if you re-oil those before assembly, or what your approach might otherwise be regarding the little bit of lube they require. Bummer about the stalling issue. Maybe a quarter-ish turn leaner on idle mix, for this warmer weather? Or - time for (the forum mantra)... a valve adjustment?!  They do seem a somewhat cantankerous little beast when hot - engine and carb soaking in all of that heat under the bodywork. I'd have to think it wouldn't be an issue with weak spark, as that would more likely show as a miss under load... Bob |

|

|

|

Post by 90GTVert on Jul 24, 2015 12:56:41 GMT -5

I don't oil it. I was under the impression that a "self lubricating" "oil impregnated bushing" had it's own lubricant within. I do clean it whenever it's apart and then sometimes I'll put a drop of oil on a rag and wipe the bushing and boss, then wipe with a clean rag. More or less just a film. Seems to make no difference either way and at this point the bushing appears to have outlasted the rest of the variator anyway, which is a bit sad for something with under 2000 miles on it in a stock 49cc. I have heard of people trying to refresh these bearings with hot oil baths and applying vacuum and things like that, but replacement seems much easier to me.

I checked the valve adjustment I think twice in the last month. Roughly 10 checks in under 4000 miles.

It runs anywhere from 14.7-16:1 at idle or when I let out of the throttle like that. Depends on exact conditions and how warm the engine is. Pretty much what it's done the whole time I've owned it. Prob the only odd thing I've noticed with the tune is that I've had to move the needle clip up to lean it more and use a slightly smaller jet to get the same tune that I had last summer. I'm not noticing anything strange in the carb though, and as posted above it's on par for the most part. Tried checking for any changes both misting water and using an unlit propane torch too and it never missed a beat.

|

|

|

|

Post by 49dykon on Jul 26, 2015 11:03:21 GMT -5

Any idea what's going on with the scoot dying at a stop?

|

|

|

|

Post by 90GTVert on Jul 26, 2015 18:37:09 GMT -5

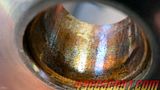

I've rode it a few times and went at stop signs WOT then braked kinda quickly and it hasn't happened. I did see that the pilot jet looked clogged. I couldn't see through it when I held it up to a light, but I wrote down my idle mixture setting and put it exactly the same way when it went back together and nothing changed. Not sure if perhaps whatever was in there could move when there was flow, maybe something to do with when the air cutoff valve worked it would then block the pilot. Not sure. I did a couple of sets of 0-30s with the new variator yesterday. The first was with 5.5g sliders. RPM seemed a little low to me for the 0-30 runs, but about right for cruising. I put a blue mark on the variator before the ride to do the test runs and it had what I'd call normal belt travel. About what I'm used to seeing. Even though RPM seemed too high for me at cruise, I tried 5.25g sliders as well for some 0-30s. I marked the variator with a red mark beside the blue one so I could see how much less travel there was... about 0.7mm difference.  I really thought the 5.25g sliders were going to be quicker 0-30MPH but the 5.5s would be what I'd go with because of cruise RPM even with some sacrifice of acceleration. For that reason I never tried 5.75g weights yesterday when the winds were 5MPH or less and conditions were pretty nice for test runs. I went in and checked the vids to time the runs and it turns out the 5.25g setup was actually slower by up to a second on average. I suppose the sound of high RPM must trick me into thinking I'm going quicker or something? Either way, that's why I get numbers and not just feelings when I tune. I think what was happening is that it would pull harder on takeoff, but by the time it was close to 30MPH with the lighter weights it was over it's peak power and it struggles the most in the last few MPH so it suffered there. I planned to take it out today to try 5.75g, even though I believe it will be slower 0-30 and struggle more to maintain cruise speeds at lower RPM. Didn't work out though. Winds started off around 10MPH and now they're gusting nearer 20MPH. I try to keep test runs with this thing to times when winds are closer to 5MPH or less ideally. It's so underpowered that even a few MPH wind if it's anywhere near direct can throw it off pulling the last few MPH to 30 and I'm afraid that even averages going in each direction won't be accurate reflections of changes. I think the weather is supposed to be bad for a couple of days, but the new NCY TD should arrive Tuesday according to tracking. Here are some pics I took of the vari and bushing after the first ~17 mile ride just to show the wear that's almost immediate as well as the oil residue from the oilite bushing.     When I put the TaoTao on it's center stand on the scoot workbench, I put my arm under the rear of it and lift it up while I put the stand down with the other hand. I broke the plastic stud off that secures my LED turn signal when I hit it with my arm. Ended up using double-sided 3M tape to stick the light to the panel.  |

|

|

|

Post by 90GTVert on Jul 29, 2015 14:58:15 GMT -5

I tried the heavier weights out just in case it would surprise me, but it didn't. It went quite a bit slower trying 0-30s and cruise speeds were no better or a little worse. The new NCY torque driver came in from Enviromoto yesterday. Looks the same as what I had, just without the wear.   I swapped it out today and dug out some pins that didn't have flat spots to use, but it's windy once again so I haven't tried to do any test runs. I doubt that it will improve or not much, but at least I'll feel better not having the worn parts in there.  Now I'm looking at the pic and being reminded that I had to grind down the lip on the old NCY so there was no contact between the moveable half and the clutch. Guess I'll be taking it back apart to check that. |

|

|

|

Post by 90GTVert on Aug 1, 2015 14:55:30 GMT -5

I took the rear pulley off and took the contra spring out to check for clearances the other day and it did need work. Here's another reminder that "bolt-ons" don't always work 100% if all you do is bolt them on. The pulley lifted the clutch (testing without the nut installed) at full travel, so I started by grinding down the top of the torque driver a little. I also shaved the seal with a razor so it didn't stick up above the torque driver.  Then the bottom of the clutch shoes and it's pins were hitting the pulley. I had already ground the clutch about as much as I could when I used the last NCY torque driver. Grinding farther wouldn't get me anywhere because the pins would still need to be there and clutch springs would be sticking up above the shoes. I used a spacer between the rear pulley and the clutch to separate the two a bit. It was just enough to do the job. Any more spacing and the nut wouldn't be able to go on very far.   Once that was all good, I put the clutch bell on and tested again. Then the raised edges of the pulley hit the edges of the clutch bell. I put the pulley on the drive shaft so it would spin with the power of a grinder for even cutting and shaved it pretty much completely off. Then I filed and sanded the edges so they weren't sharp. Finally it all went together with no interference at full travel. The last NCY unit needed most of the same work, but required no spacer. AFAIK they're the same torque drivers.   I did 8 0-30s runs with 5.25g and 8 0-30s with 5.5g, both of the closest to what usually works, and both are slower than it was before.  Both were also about the same, even though I really though the lighter weights had an advantage based on the RPM it stayed at. It was hot and a little windy so I'll retry to be sure that's the right result. I'm using the steeper angles of the TD, that always did best with the last one, but if it's slow when I try 0-30s one more time I may switch it to the lesser angles just to be sure. The last month or more has been nothing but testing and swapping and tuning to get nowhere. Runs fine. Real world I can't tell much difference in now and it's best times, but on paper it looks worse that when I last did any videos. |

|

|

|

Post by 90GTVert on Aug 3, 2015 10:42:03 GMT -5

This scooter is crazy and it's making me crazy. lol Some 0-30 results to maybe give you an idea of why (in chronological order) : Setup

| 0-30MPH Time

| 0-30MPH RPM

| Old NCY TD (Steepest Grooves)

New Replacement Var w/Oilite Bushing

5.5g Sliders, 1K Contra, 2K Clutch

| 18.45

| 7600-8000

| Old NCY TD (Steepest Grooves)

New Replacement Var w/Oilite Bushing

5.25g Sliders, 1K Contra, 2K Clutch

| 19.48

| 78/7900-82/8300

| Old NCY TD (Steepest Grooves)

New Replacement Var w/Oilite Bushing

5.75g Sliders, 1K Contra, 2K Clutch

| 20.60

| 75/7600-79/8000

| New NCY TD (Steepest Grooves)

New Replacement Var w/Oilite Bushing

5.5g Sliders, 1K Contra, 2K Clutch

| 19.47

| 7400-7900

| New NCY TD (Steepest Grooves)

New Replacement Var w/Oilite Bushing

5.25g Sliders, 1K Contra, 2K Clutch

| 19.80

| 75/7600-80/8100

| New NCY TD (Steepest Grooves)

New Replacement Var w/Oilite Bushing

5.25g Sliders, 1K Contra, 2K Clutch

Re-Try

| 20.44

| 7900-8300

| New NCY TD (Steepest Grooves)

New Replacement Var w/Oilite Bushing

5.5g Sliders, 1K Contra, 2K Clutch

Re-Try

| 21.82

| 7700-8300

|

So far the new TD is not keeping the RPM quite as tight. Even times when RPM on the setups look pretty close to what the best was, they are sometimes way off. It seems like any little change can add a second or more. I have no idea why the latest setup suddenly made RPM increase quite a bit. Notice the 5.5g setup went up by 3-400RPM doing 0-30s. I noted cruising around at 77-8000RPM @ 32-34MPH at first with that 5.5g setup. On the last ride I was seeing as much as 84-8500 @ 34MPH with everything setup the same way. It doesn't seem like the belt slipping, as if perhaps some grease escaped the TD for example. The belt is fairly new and I wouldn't expect it to wear that much so quickly. I'll have to take it apart again and get a better look. At first I thought something is just getting settled in after a bit of riding, and didn't really pay much attention when I did a real quick slider swap thinking heavier weights would put it back on track. Didn't expect my cruise RPM and the end of the 30MPH run RPM to be the same or higher with the heavier weights. I miss just riding a scooter and not recording it's every move. lol Hopefully this will give you an idea of why there have been no updates even though I said they were coming. I just want it to be consistent, without worn out part so hopefully it stays consistent, and preferably somewhere near the old times (I'd gladly accept consistent 18s). EDIT : And just so you know why I don't go back to the old NCY TD, it had worn places in the grooves shown in previous posts. One more note, old setup from the last vid with times was a best of 17.76 average and RPM stayed quite near 8000-8100 for the 0-30. That was a stock vari, NCY TD so nothing really much different although every stock or stock replacement vari seems to act at least a little different. Small design changes equaling large effects (if you scrutinize each setup, prob not easily perceived just riding around in many cases). |

|

|

|

Post by 90GTVert on Aug 4, 2015 18:31:55 GMT -5

After the revs changing over a brief period of time, I took the CVT apart to see if there was grease being thrown around or anything obvious. There was indeed a little grease that had escaped the torque driver. Nothing terrible. A couple of tracks on the TD and a little grease thrown on the CVT cover around the rear pulley.   The variator had a lot of grey/black on it's face.  The belt had a minor glaze on the side that matches up with the variator. Not that a glaze really worries me since pretty much every belt gets glazed in my scoots.  I found a tiny oil leak at the crank seal. This is nothing compared to my usual leaks with this thing. It's been good for quite a while, without leaving me a dime to quarter sized puddle under the back of the CVT (runs downhill) when parked after a long ride. Even when it leaks that bad, it hasn't caused me any trouble with the pulleys so far.  I cleaned everything up to get the grease and oil off including parts that didn't even seem to have any residue on them. I quickly sanded the variator prior to cleaning it.  I put it back together and took it for a quick ride. It was in the 90s, windy, and humid so not really ideal conditions... mostly the wind sucks for checking CVT tune. I left and it was revving high. It settled a little over the first mile or so. That's nothing unusual. It seemed to keep settling though. At one point it was hitting 8000-8200RPM at 30MPH. By the time I was almost home it was as low as 7500RPM at around that speed bogging into the wind and probably a few hundred RPM higher without the wind head-on. I was hoping that I had cleaned off the grease and maybe the belt just wasn't totally dry or something along those lines when I started the ride. I let it set for a while and then took another ride. It again left revving a little high, but settled. On this ride it actually stayed at a better cruise RPM most of the time, not reaching up above 8200RPM much unless I caught a tail wind and sped up. Maybe there's hope... ...Then it died on me when I came to a stop sign. It wouldn't restart. I pushed it about a half mile to some shade and eventually it did start and I rode it home. I thought that was over after the carb cleaning. Hasn't done it on multiple rides. I'll get together some more on that later and post it up in case anyone has ideas. I think I have all three times it's broken down on me on video. |

|

|

|

Post by 190mech on Aug 4, 2015 20:00:08 GMT -5

Iggy related shutoff?Once cool starts again..

|

|