|

|

Post by 2TDave on Sept 15, 2014 18:18:50 GMT -5

I'm waiting on the stroker crank to get here. I've got a set of good 50 long case for it to go in. I'll probably grind it myself. Gives me something to do when my pita step daughter is visiting with all of her drama. I think I'll put a bunk and a bucket out here.

|

|

|

|

Post by 190mech on Sept 15, 2014 19:06:34 GMT -5

|

|

|

|

Post by oldgeek on Sept 15, 2014 21:00:13 GMT -5

On another note, are the crank wheels on your new crank any thicker? I know the diameter is larger and that has to be cut but will they drop in and the cases bolt up when the diameter is increased? I have not measured, but I am pretty sure they are the same thickness as the 50cc, or else you would really have to do some fancy case work. |

|

|

|

Post by jareeb on Sept 16, 2014 10:16:17 GMT -5

cheapest place to buy burrs. very good quality as well. he once charged me to much for shipping and he didnt say anything and refunded me the over charged amount, its the only place ill ever buy burrs from.

|

|

|

|

Post by oldgeek on Sept 16, 2014 21:05:02 GMT -5

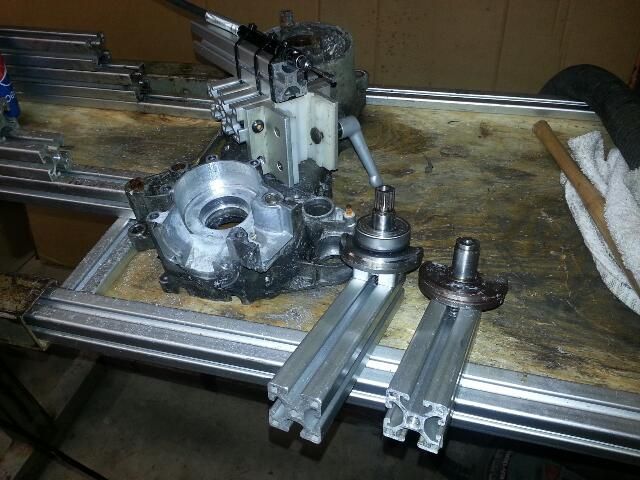

I worked on building the jig today in my spare time. About about 3 hours total. As you can see I ditched the concentric pulley, mostly because the pulley was used, and just had too much slop in it. I ended up using some t-slot extrusion. I love working with t-slot, all you need is something to cut it fairly square and a drill and you are in business! I think the jig would work as it is ok, but I want to add a vertical slide just like the horizontal slide to make cutting the big half of the case easier. I believe this thing may actually work!  |

|

|

|

Post by oldgeek on Sept 16, 2014 21:06:08 GMT -5

cheapest place to buy burrs. very good quality as well. he once charged me to much for shipping and he didnt say anything and refunded me the over charged amount, its the only place ill ever buy burrs from. Do you have a link where to buy them? |

|

|

|

Post by jareeb on Sept 16, 2014 22:19:10 GMT -5

|

|

|

|

Post by oldgeek on Sept 17, 2014 21:23:09 GMT -5

I took the last items I needed to the warehouse, and decided to give the trimming tool a try just as it is. It was just a quick test to see if the concept will work. I used a small case half one of our forum members let me have. One of the exhaust mounts is broken off, but it does not matter for this test/practice run. The first pass removed about 1.5mm and is the one I took a video of. The second/last pass removed approximately another 2.5mm. About 4mm total was removed which is just a little (.5mm) too much for this case I think, as I got pretty close to the bolt holes. The crank I test fit is a new stock 90cc which measured 77.95mm. The diameter of the cut case ended up being 80mm. I could have left another .5 - 1.0 mm of material on the case, but I did not measure anything as I did it, just after I got back home. I think it came out rather well, but, this is the easy side of the case to do. A different trimming tool will have to be made for the large case half. The design will be the same, but the dimensions will be different. Another thing I may change is the size of the flex tool, and the cutter. While it worked, I think more power would make things faster and easier. Possibly a roto zip flex tool that will accept the larger 1/4 shank burrs.      |

|

|

|

Post by 90GTVert on Sept 17, 2014 22:07:53 GMT -5

Nice. Thanks for showing it to us in action. Looks pretty quick and simple with your creation.

|

|

|

|

Post by 190mech on Sept 18, 2014 3:59:27 GMT -5

Great tool!!  |

|

|

|

Post by 2TDave on Sept 18, 2014 5:18:54 GMT -5

Nice work!

|

|

|

|

Post by oldgeek on Sept 18, 2014 6:05:02 GMT -5

Thanks guys. I am 1/3 of the way there! LoL! The tool for the large case half will be similar to what I have made for the small case half so hopefully I can get that done soon. I have not given much thought to the jig need to open up the cylinder base area. I may just eyeball it by hand, or possibly try one of those "fly cutters" like NYC sells for about $125. I will cross that bridge when I get there.

|

|

|

|

Post by Sitticuss on Sept 18, 2014 18:28:37 GMT -5

Sweet!!

|

|

|

|

Post by oldgeek on Sept 21, 2014 21:15:18 GMT -5

I started working on the tool for the big half of the case today, it took about 2 hours to get another old crank apart and grind one of the the surfaces flat so I could drill and tap a mounting hole in the center of the crank. Some how even though I used the drill press to start the tap straight it threaded crooked as hell. The next hour was spent figuring out how to salvage the assembly. All I need now is a screw long enough to reach through the spacer, and another hour or two to assemble it and it should be ready to go.  |

|

|

|

Post by oldgeek on Sept 22, 2014 20:27:05 GMT -5

I got the base assembled for the big case side tool, and 5 minuets into assembling the slider part of the tool, I realized I could just use the one I already made for the small side tool! I slid it into place and tried the tool out on a genuine jog case that has some damage. The case half used for this test came from forum member Paladin.(Thanks Paladin!). The case half came out pretty nice I think. I believe the slight ridge is caused by my spacer not being perfectly flat. I should be able to eliminate the spacer, and use a stack of washers or something similar that I know is flat. Three passes were required to do the depth of this larger case half. I did not measure how much I removed, but it looks to be around 1.5mm I just wanted to try the tool out.    |

|