|

|

Post by 190mech on Jun 3, 2014 9:19:26 GMT -5

Lookin Good!Removing some of the cylinder side webs at the transfer ducts will help flow.I check where the piston side skirt is just as the are transfers open a few MM's and raise the cyl side webs to around that spot..Taking a bit off the piston crown in the transfer port area is an easy way to get more duration if needed..  |

|

|

|

Post by 2strokd on Jun 3, 2014 14:43:19 GMT -5

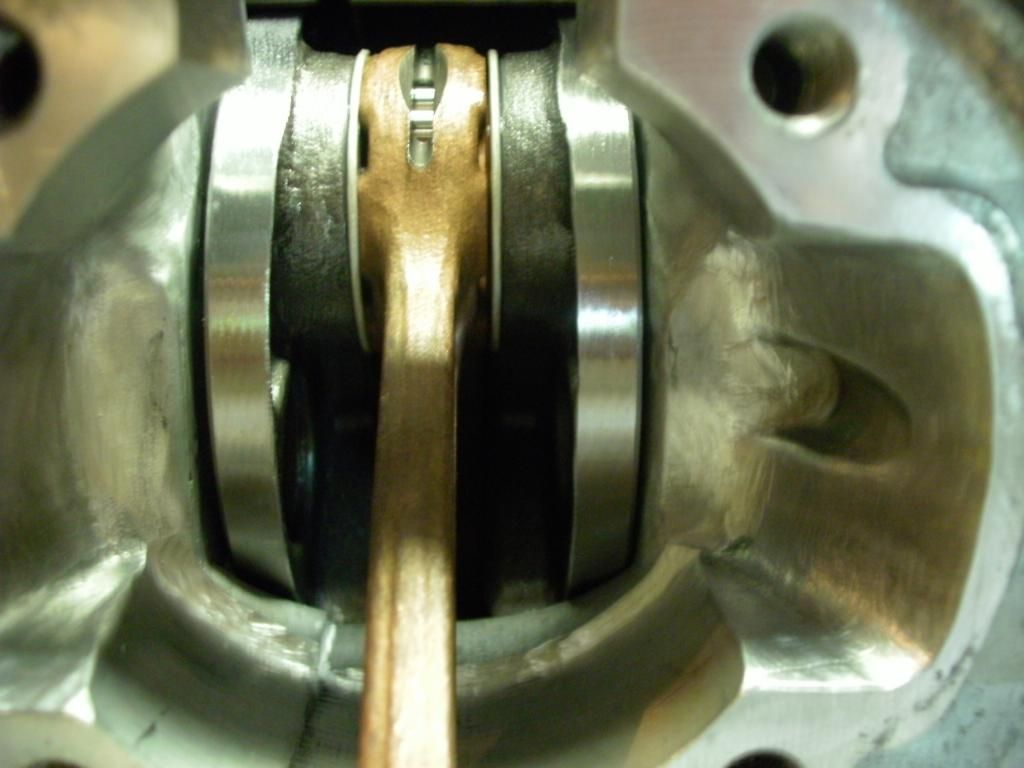

Very good idea! Got the bearings warm and the crank cold and it slid right in.. Dont forget the threebond!  Crank temp rising quick after meeting up with the hot bearing.  And the cases cooling fast from 250 after meeting up with the cold crank.  |

|

|

|

Post by 90GTVert on Jun 3, 2014 15:18:31 GMT -5

I stopped doing it with bearings in the case first. I may be wrong for that, but I found that if the case gets much heat the bearings will fall out if I moved the wrong way. With the steel bits all cold and just the aluminum hot I've had less issues aka hot bearings falling out. I didn't do it that way more than once or twice though, so I suppose if I would have sense enough not to tip the cases the wrong way it's a non-issue. Heat gun prob doesn't do this like the oven either. I used to always use the oven. Now I only use the oven for the bearings so I feel temp is more controlled and perhaps heating the cases locally is better for sealant application... although the heat propagates across the case over a short period of time but temps drop as it spreads. Wonder if your way would be even better for sealant application since you're heating a bearing in the center rather than the case (although I really haven't had issues with ThreeBond anyway)? Just curious if this is how you've grown to like assembly best or if you do it different ways? I've been stuck on crank/bearing assembly into case for quite a while now, but it never hurts to hear more on the subject.

|

|

|

|

Post by 190mech on Jun 3, 2014 20:50:46 GMT -5

Ive been troubled with case/bearing heating during assy too!Now I'm more inclined to get rid of the 'press fit' of crank to bearing so the crank can find its own center(polishing the crank journals for a slip fit)..If the bearings are heated and dropped on the crank,allowed to cool,then the cases are heated(one at a time),cool crank dropped in seems to be the best route..Gotta watch about case temps if a lot of epoxy is used for case work though.. Here is a trimmed piston dome for increased transfer duration;  |

|

|

|

Post by 2strokd on Jun 4, 2014 8:46:22 GMT -5

Ive increased trans duration like this before... Great idea! Worked well!

I actually like this method myself. Ive had no issues other than my own forgetfulness.

I put the crank in the big end first with threebond setting on the small half and a smear on the big. Dowel pins in the big end already. In the middle of heating the bearings, (cycle back and fourth from big to small end with the heat gun to try and heat them even) i apply the threebond.

It has stayed in place well for me. I try not to go over 250degrees and everything slide right together with that wonderful "click", letting me know its seated, or supposed to be.

|

|

|

|

Post by 2strokd on Jun 4, 2014 8:52:09 GMT -5

As smooth as these cases went together i still ran into trouble.

When i snugged the case bolts up and tried to spin the crank it wouldnt. It was stuck.

My guess is, and as 190 mentioned in a PM, there isnt enough room for the crank in the cases.

But why? I gotta pull it back apart and see whats causing this.?

I think i got the crank outta round by tightening the case bolts up and pinching it? I should have checked the cranks rotation/fitment before and while tightening the case bolts.

|

|

|

|

Post by 2strokd on Jun 4, 2014 8:53:59 GMT -5

It does look like one bearing is not all the way seated compared to the other.

I took a pic but havent uploaded yet.

|

|

|

|

Post by 90GTVert on Jun 4, 2014 10:03:09 GMT -5

Damn. Nothing can just be easy.

|

|

|

|

Post by moofus02 on Jun 4, 2014 14:21:42 GMT -5

Ive been troubled with case/bearing heating during assy too!Now I'm more inclined to get rid of the 'press fit' of crank to bearing so the crank can find its own center(polishing the crank journals for a slip fit)..If the bearings are heated and dropped on the crank,allowed to cool,then the cases are heated(one at a time),cool crank dropped in seems to be the best route..Gotta watch about case temps if a lot of epoxy is used for case work though.. Here is a trimmed piston dome for increased transfer duration;  Hey John when you polish the crank for a slip fit in the bearings so it self centers how much side to side movement do you get? Enough to cause problems with crank seals? Just wondering after Brent's trouble with a loose bearing in his case. Sent from my SPH-L720 using proboards |

|

|

|

Post by 190mech on Jun 4, 2014 19:42:02 GMT -5

The Minarelli's have very little side clearance,some of the old school MX bikes needed to be shimmed which was a tough task..If a crank walks .25mm side to side,the seal should not leak..

|

|

|

|

Post by moofus02 on Jun 4, 2014 20:20:34 GMT -5

The Minarelli's have very little side clearance,some of the old school MX bikes needed to be shimmed which was a tough task..If a crank walks .25mm side to side,the seal should not leak.. That's the info I needed so when I do a mock up if I have that our more shim the bearings in to take up the exes Sent from my SPH-L720 using proboards |

|

|

|

Post by 190mech on Jun 5, 2014 4:34:12 GMT -5

|

|

|

|

Post by moofus02 on Jun 5, 2014 4:44:10 GMT -5

Thanks John Sent from my SPH-L720 using proboards |

|

|

|

Post by 2strokd on Jun 7, 2014 9:54:49 GMT -5

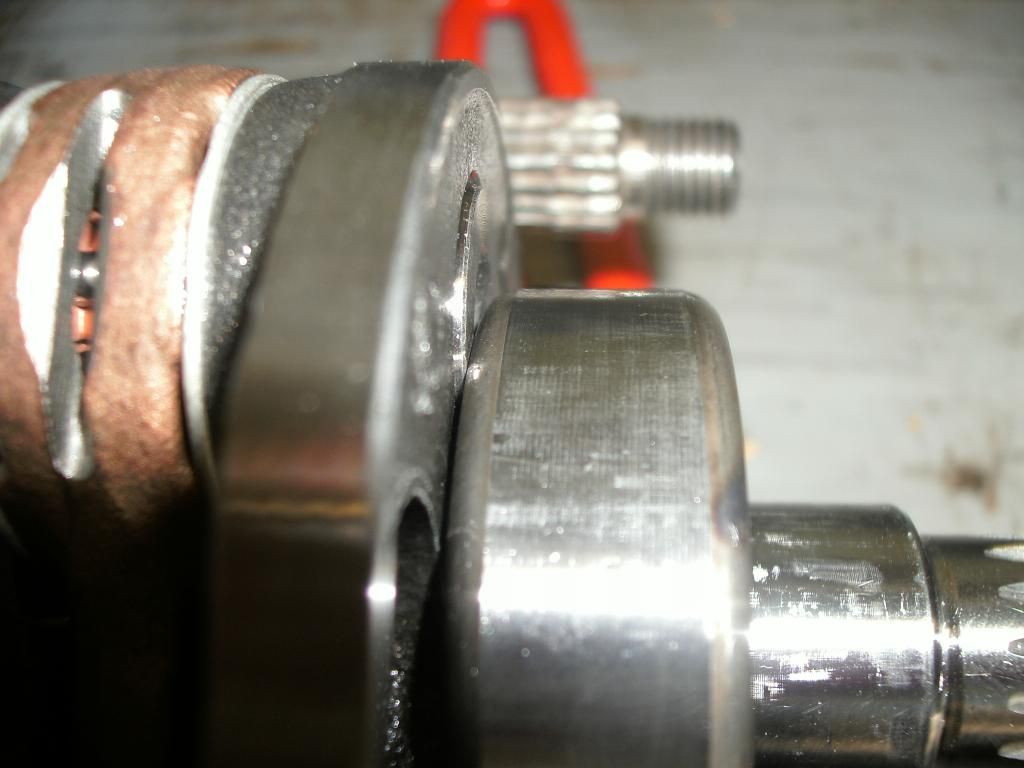

I took the crank back out and the only thing i can see that might cause interference is the big end pin. Somehow it got like this...    I checked it with a feeler gauge and it is definitely scrubbing the case.  You can kinda see in this pic were it looks like the pin left a mark in the case.  Checked the OD of the stock crank and the 42mm stroke just to be sure. Stock 37.83mm  42mm stroke 37.72mm  At the OD of the bearings, 42mm stroke crank  Stock crank  I am hoping i can move the pin a tad and true the crank back up to try this again... Any input or thoughts, suggestions. |

|

|

|

Post by 2strokd on Jun 7, 2014 12:17:17 GMT -5

A great vid on truing 2T cranks 190mech shared with me.

Thanks 190mech!

|

|