|

|

Post by pitobread on Jun 17, 2018 15:19:39 GMT -5

Don't put your aluminum bore in muriatic acid to remove aluminum from the plating  You can always send it to Mongoose Machine with your new piston, they will re plate it and fix any gouges and send it back as new. I think they are even in Alberta somewhere? It looks like a big gouge above the transfer, but hopefully it cleans up... |

|

|

|

Post by pitobread on Jun 15, 2018 1:04:48 GMT -5

Bring the revs up, pull the choke and repeat the string out on the stand, if it clears up your too lean on the top.

|

|

|

|

Post by pitobread on Jun 11, 2018 1:40:44 GMT -5

Also consider the tire grows at speed a considerable amount, and under breaking the forks will bend backwards slightly

You need to have a good amount of clearance!

|

|

|

|

Post by pitobread on Jun 10, 2018 11:48:38 GMT -5

That is the end of an era. in the box is a honda twin kit, going to the states.  Goin back to single. Albeit probably a fast single.   The old Dio's 82cc build... for now. But that may change |

|

|

|

Post by pitobread on Jun 9, 2018 12:36:53 GMT -5

|

|

|

|

Post by pitobread on Jun 9, 2018 12:32:16 GMT -5

I have found them on aliexpress for very cheap.. just a simple k type thermocouple. I know koso ($$$$) make some "fast" egt but it is usually just the thermistor is exposed, you can do this to a regular thermocouple yourself with a little patience.

|

|

|

|

Post by pitobread on Jun 7, 2018 0:39:29 GMT -5

So these are the tools you need to make to take this apart. 1-9/16 hole cut in a plate then cut in half, then a 14mm and the same, you can then clamp the shock shaft and the shock body in the vice to take the end and the yoke off.  So set the piston depth, then fill the chamber and insert the piston and shaft.. you need to work the bubbles out. Lift the dampening rod up so its easier to pump and pump it till the bubbles stop, tap the sides then pump more.... then take a break and pump it again. Then fill it to the top again and insert the seal head into position  Then pump it again.. and again, tip it around, tap the sides and pump it. When i did this step and installed the clip it had some trapped air so i pulled the c clip and washer and re did it.. you can feel the trapped air when you change direction or get to the ends of the travel.. it will get momentarily easy.. if that is the case, you have to redo this step. Also you want to keep the little hole here covered with oil so you want to top it up and pump slowly, otherwise you can just pump more air back in.  Then install your seal, clip and washer. make sure you have the tube full of oil when you push the seal in again so you don't trap air under it. i tipped mine around a bit.  Then your done with that end.. next up nitrogen fill.  |

|

|

|

Post by pitobread on Jun 6, 2018 10:46:21 GMT -5

I have people that have said they contacted them no issues. But they basically ghosted me for whatever reason.

Paioli has no contact info available whatsoever. I don't think they want to talk to you unless your ordering 1000 of something.

I'm fixing it either way. Just highly annoying.

|

|

|

|

Post by pitobread on Jun 6, 2018 1:15:24 GMT -5

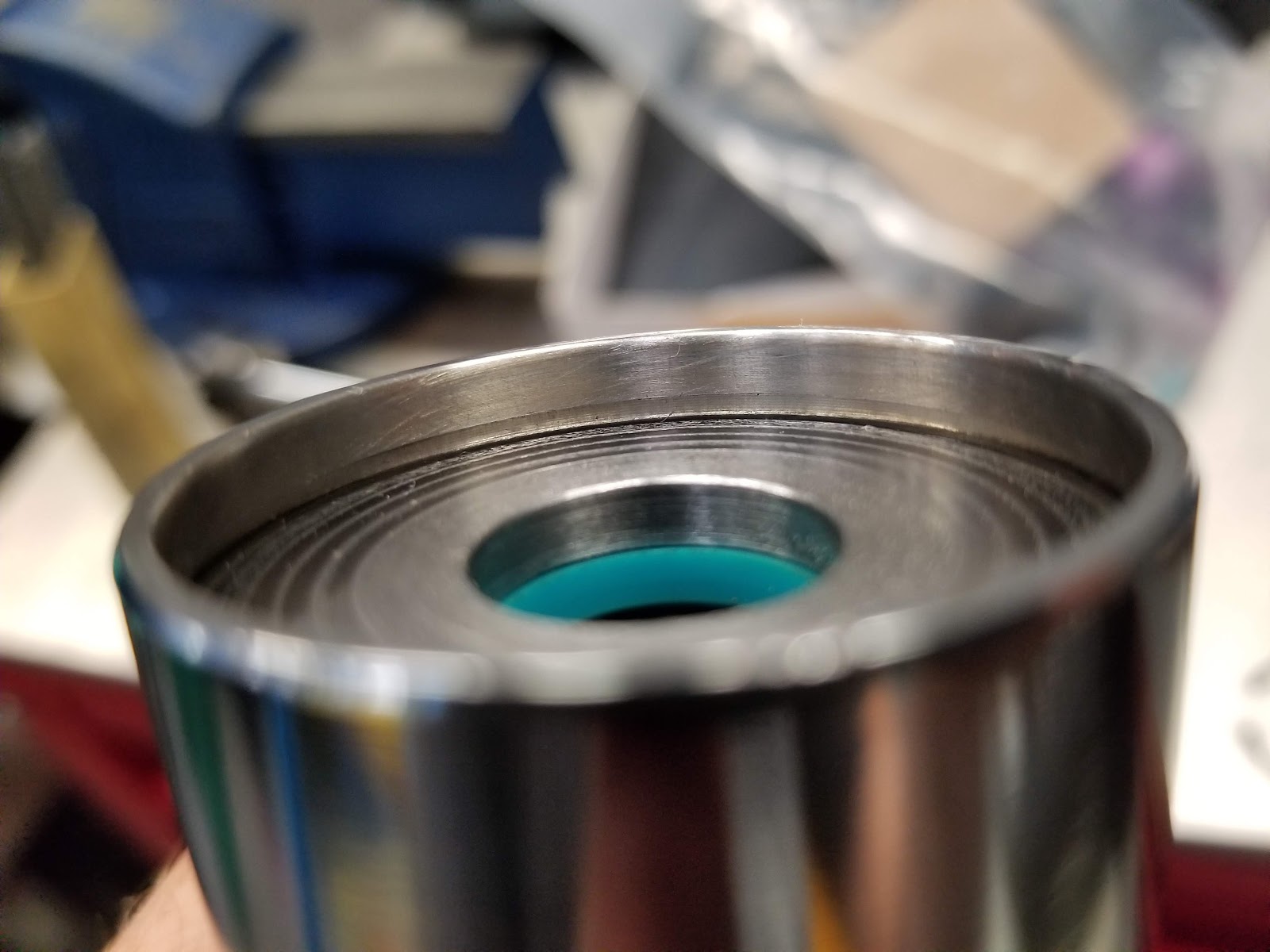

Well my new RS24 shock leaks. I tried to contact Malossi via their website and their instagram feed and got nowhere.  That is pretty disheartening considering I hold their products in pretty high regard to literally not hear back from anyone even to say they won't warranty or fix it. So I took it apart, It is a "non serviceable" shock. It has no provisions to refill the nitrogen once it is released. I however am just going to add the provision to do so via either a needle fill or a schrader valve. So lets look inside! Disassembly was medium difficulty. Inside the top eyelet is just the gas chamber, using an electric heatgun to soften the thread sealant it opens up to nothing, also nothing can come out this way either. There is a step preventing it. Also if you shock has pressure this is the end you have to be the most careful with. either drill a small hole you will later use for your fill valve or turn slowly. Malossi Charges these with 10 Atmosphere of nitrogen, it will make a big pop if you let it out at once. So you have to take the bottom yoke, again using the heatgun method to soften the thread sealant. once that is off you have to pry the decorative cover off the bottom that also houses the dust shield. Once that is out of the way you end up with a circlip and washer, then the seal head and all the oil and the valve will slide out. So I couldn't see where mine was leaking from, but after some head scratching I think I figured it out. I think the seal head or the shock body are mis machined.  So the washer should have a positive engagement on the seal to keep it in place and the pressure from leaking behind it. But as we can see there is a gap. So I machined up a new washer  It actually requires you to push the seal in slightly when you install the snap ring.  I installed new orings, and installed the gas chamber piston in at a height of 22mm.. kinda an educated guess.  Then taped the threads to keep from cutting the seal and installed the seal head and seal  Next up is adding the fill in the top cap and adding oil. |

|

|

|

Post by pitobread on Jun 5, 2018 22:54:48 GMT -5

Oh, and I ordered Malossi RS24 rear shock and forks for this bad boyyyee.

|

|

|

|

Post by pitobread on Jun 5, 2018 22:54:09 GMT -5

Got bored. 3.0 x10 slick stretched on the wide typhoon wheels.  Probably going to be on 10"... I just can't get used to the 12"  It also makes it shorter and more zip like. Did I mention I really want a Zip? Still need to find a euro headlight.. |

|

|

|

Post by pitobread on Jun 5, 2018 22:50:19 GMT -5

This is what it looks like when it's not 11pm and you actually fit the panels.  |

|

|

|

Post by pitobread on Jun 3, 2018 23:28:44 GMT -5

You want to run that screen it keeps dirt/debris from jamming up the petcock.

|

|

|

|

Post by pitobread on Jun 3, 2018 1:39:24 GMT -5

Not done yet, got a few more things to wrap up then it's gone out of my garage. Discuss. |

|

|

|

Post by pitobread on May 30, 2018 20:35:56 GMT -5

Stock most scootys use a single. With an M10 bolt in there you would probably bend the shock shaft before you broke the bolt or the mount.

On my Spree I used an M8 bolt to hold my shock on that I screwed into a lug I tapped on the frame. I think your M10 will give you an excellent safety margin.

|

|